Case Studies

Artisan Fine Foods

This case study showcases the deployment of our solution at Artisan Fine Foods, a prominent seafood distributor known for its commitment to freshness and quality. The system was implemented to provide accurate, real-time monitoring of temperature-sensitive seafood across storage, where consistent temperature control is essential to preserve product quality and ensure food safety.

Company Profile

Artisan Fine Foods is a Singapore-based importer and distributor of premium ingredients sourced directly from producers around the world. Known for its focus on product integrity and supplier relationships, the company offers a curated range, from USDA beef and Iberico pork to air-flown seafood and gourmet desserts. Artisan is also committed to introducing unique, high-quality products to the local market by sharing the stories behind each brand and inspiring new culinary trends.

Challenges

Artisan Fine Foods faced critical cold storage challenges.

Solution

The IoT solution delivered real-time control and compliance confidence.

Key Components of the Solution:

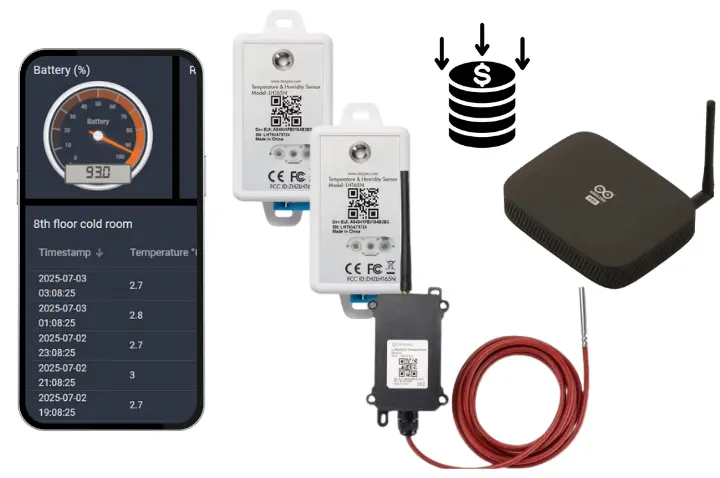

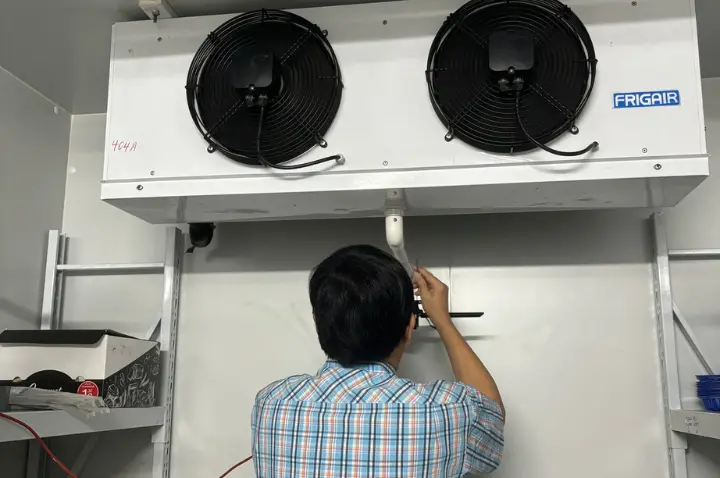

IoT Sensor

The sensor is placed inside cold rooms and is built for use in low-temperature environments. It is ideal for continuous temperature monitoring to ensure product safety and compliance.

IoT Gateway

The gateway plays a crucial role in facilitating continuous and seamless transmission of data to the cloud. This setup enables efficient and reliable real-time temperature monitoring.

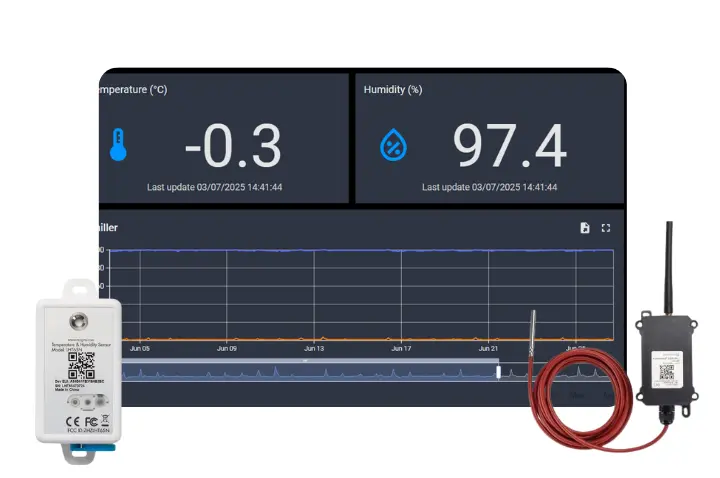

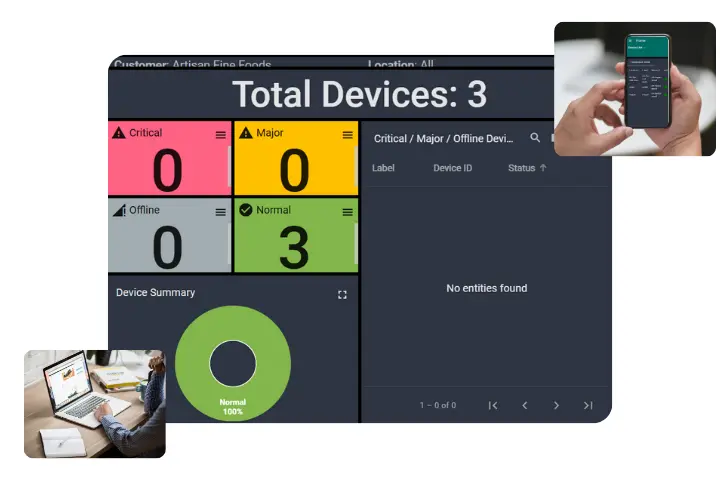

Monitoring Dashboard

The cloud-based dashboard enables users to remotely view temperature trends, receive alerts when parameters are breached, and download detailed reports on temperature fluctuations.

Benefits

1. Cost Savings:

Artisan Fine Foods can now avoid product loss, spoilage, and unnecessary energy consumption. With IOT-ezy automated system, it detects temperature fluctuations in real time, allowing you to act before issues become costly. Reduce manual labour and prevent expensive equipment failures with intelligent monitoring.

2. Data Logging and Compliance:

Maintain compliance with standards such as HACCP. IOT-ezy temperature monitoring system automatically records temperature readings. This data can be accessed at any time for audits, regulatory inspections, or internal quality checks. By eliminating manual recordkeeping, the system reduces the risk of human error, missing data, and non-compliance, all while helping you uphold the highest standards of food safety.

3. Time Saving Automation:

Artisan Fine Food now can free up their team from repetitive, manual temperature checks and focus on other operations matter. Our system continuously monitors your environment, logs data, and sends alerts to respective users if conditions go out of range. This ensures timely response, reduces the risk of product spoilage, and allows staff to prioritize productivity and quality assurance throughout daily operations.

4. Remote Access and Centralized Dashboard:

Artisan Fine Foods can access their temperature data across multiple sites, all from a single, centralized platform on any device. IOT-ezy user-friendly dashboard provides complete visibility and control over your cold chain operations, whether on-site or working remotely. You can easily monitor conditions in real time, manage alerts, analyse trends, and respond to issues as they arise at anytime, anywhere.

Outcome and Conclusion

With IOTezy, Artisan Fine Foods can:

Ready to make work easy?

Get started with IOTezy, the tech behind workflow optimization.