Laboratory Monitoring

Ensure cold chain compliance with Real-Time IoT Monitoring

Challenges in Laboratory

Maintaining strict temperature control across storage and transportation is critical but challenging. Many organizations still rely on manual logging and periodic checks, which are prone to errors, delayed responses, and incomplete records. These gaps increase the risk of product spoilage, compliance violations, and costly losses.

Manual Temperature Logging

Inconsistent Cold Chain Management

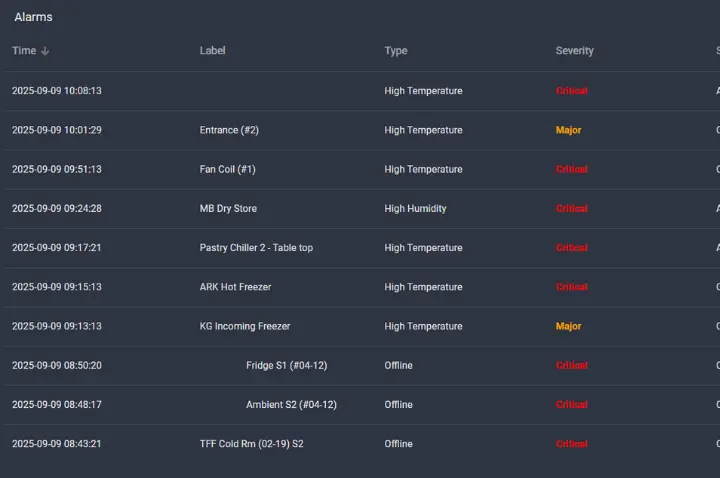

Delayed Response to Equipment Failures

Audit and Compliance Pressure

Lack of Centralized Monitoring

Why It Matters

Protects Sensitive Samples

Ensures biological samples, reagents, and chemicals are stored within required temperature ranges to prevent spoilage or data loss.

Enables Rapid Response

Instant alerts allow lab staff to act immediately when temperatures go out of range, reducing the risk of costly damage or contamination.

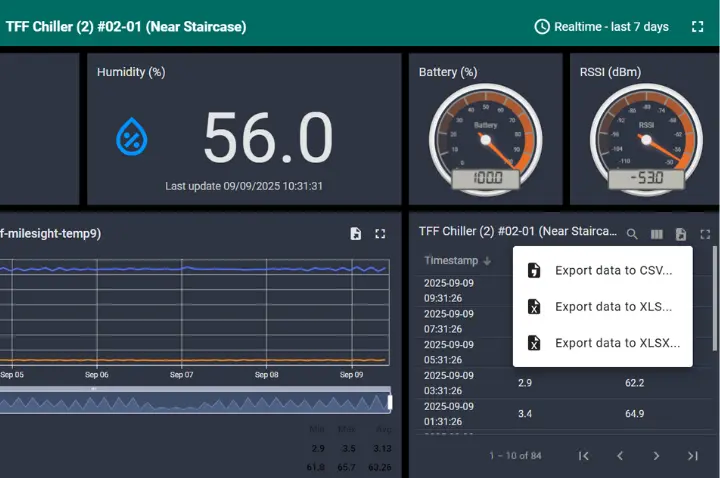

Maintains Regulatory Compliance

Automated logging supports compliance with standards like GDP, GMP and audit requirements by providing accurate, tamper-proof records.

Reduces Human Error

Eliminates the need for manual temperature checks and logs, minimizing the chance of oversight or inaccurate entries.

Provides 24/7 Monitoring

Keeps lab environments monitored around the clock. Ensuring nothing slips through the cracks.

Centralizes Data for Easy Access

All temperature data is stored and accessible from a single dashboard, simplifying monitoring across multiple units or facilities.

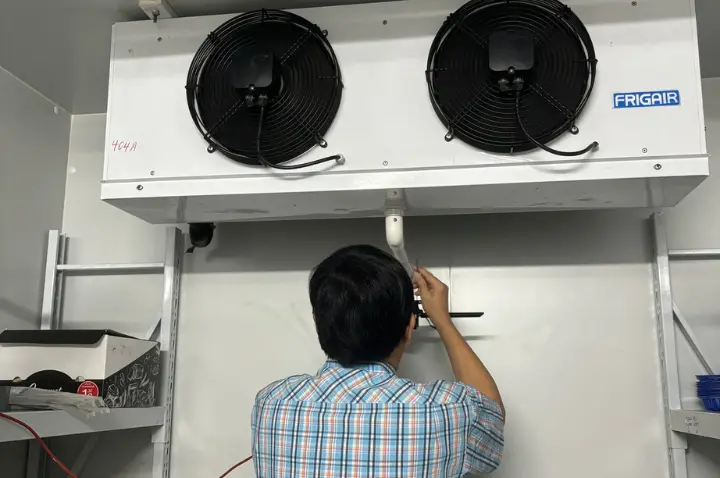

How Did We Solve It?

Solutions Used

Key Features

Ready to make work easy?

Get started with IOTezy, the tech behind workflow optimization.