Frozen Food Storage

Real-time insights to protect food and beverage integrity and meet compliance standards.

Challenges in Frozen Food Storage

F&B businesses struggle with maintaining consistent cold storage conditions, risking product spoilage, safety violations, and failed audits due to manual temperature checks and delayed responses to equipment failure.

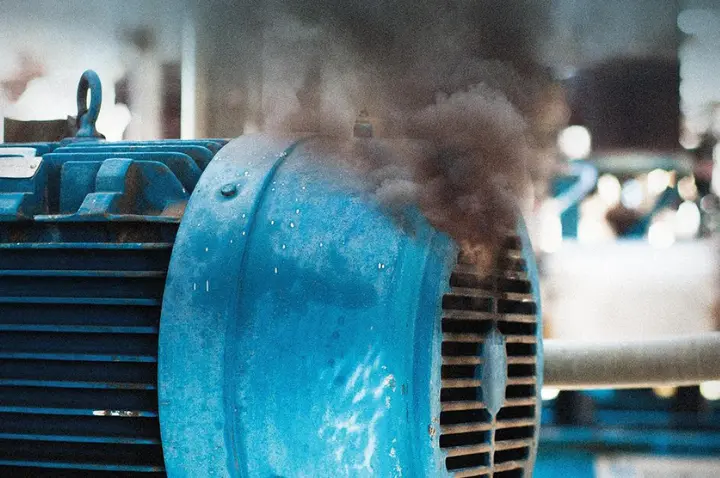

Equipment Failure Without Warning

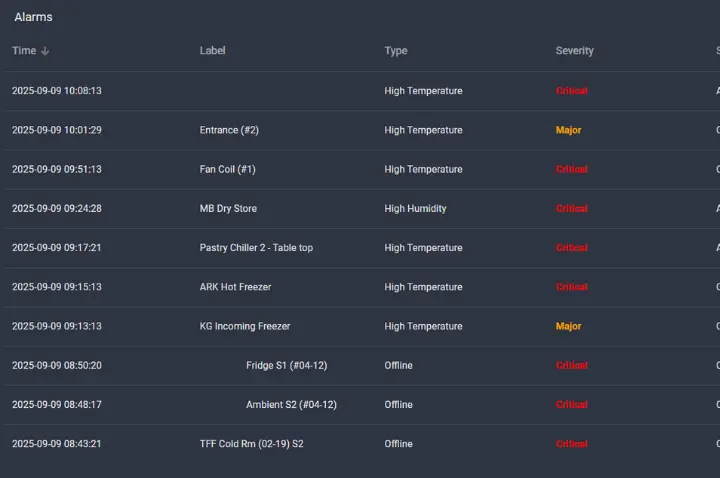

Lack of Real Time Visibility and Intervention

Manual Temperature Logging Errors

High Rate of Product Spoilage

Strict Regulatory Compliance

Why It Matters

Prevents Costly Product Loss

Instant alerts help you act fast during equipment failures, minimizing inventory damage and financial losses.

Reduces Human Error

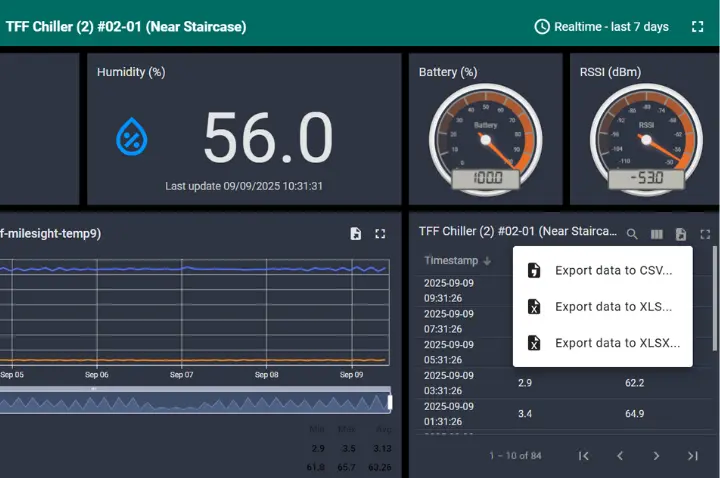

Eliminates manual logging and oversight gaps, ensuring accurate and reliable data at all times.

Meets Regulatory Requirements

Supports compliance with food safety standards like HACCP, ISO, and SFA guidelines, with automated, traceable records.

Ensures Food Safety & Quality

Maintains proper storage conditions to prevent spoilage, contamination, and health risks protecting both consumers and your brand.

Enables 24/7 Monitoring

Provides round-the-clock oversight of storage and transport conditions even outside of working hours.

Improves Operational Efficiency

Centralized dashboards and automated reports save time, streamline audits, and give teams more control across multiple sites or facilities.

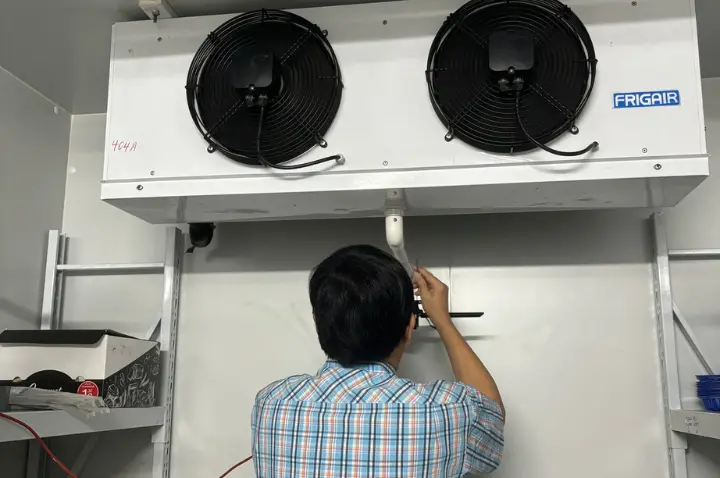

How Did We Solve It?

Solutions Used

Key Features

Ready to make work easy?

Get started with IOTezy, the tech behind workflow optimization.