Enabling Smarter Indoor Air Quality Monitoring with IOT-ezy and Atomsenses

As environmental awareness grows, businesses and institutions are looking for scalable, real-time solutions to monitor indoor air quality (IAQ). In collaboration with Atomsenses, a leading IoT LoRaWAN hardware manufacturer and IOTezy enables smart IAQ deployments across industries with seamless cloud-based monitoring and data analytics.

About the IAQ Sensor Series by Atomsenses

Atomsenses IAQ sensor series is designed for versatility, integrating 2 to 13 environmental parameters including:

- PM2.5, PM10

- CO₂, TVOCs

- Temperature & Humidity

- Light, Noise, Pressure

- PIR (occupancy sensing)

The sensors are available in 5-in-1 and 10-in-1 configurations, ideal for commercial, research, and industrial applications.

Real-World Deployments

1. Singapore Commercial Buildings – Live Air Quality Management

In an ongoing project in Singapore, Atomsenses IAQ sensors are deployed in commercial office buildings. Paired with the IOTezy cloud monitoring platform, building managers can access:

- Real-time dashboards

- Threshold-based alerts

- Historical trends for compliance and optimization

This enables smarter HVAC management and improved indoor comfort, especially in high-traffic zones.

2. Hong Kong Hetao Science Park – Research-Grade Monitoring In 2024, the IAQ sensor system was deployed in Hong Kong’s Hetao Science Park, supporting air quality monitoring in labs and innovation centres. The ability to track up to 13 parameters in one device ensures precision and adaptability which is vital in sensitive research environments.

The Role of IOTezy: From Hardware to Insight

While Atomsenses provides robust LoRaWAN-based hardware, IOT-ezy’s cloud platform delivers the interface and intelligence to make it useful:

- Dashboard for live monitoring

- Alerting via email, WhatsApp, and more

- Data export for reports or audit

IOTezy ensures a frictionless journey from data to action.

Why This Matters

- Flexibility: Choose from multiple sensor configurations and parameters

- Interoperability: Easily integrate with third-party platforms or building systems

- Future-ready: Smart building certifications, and occupant health standards

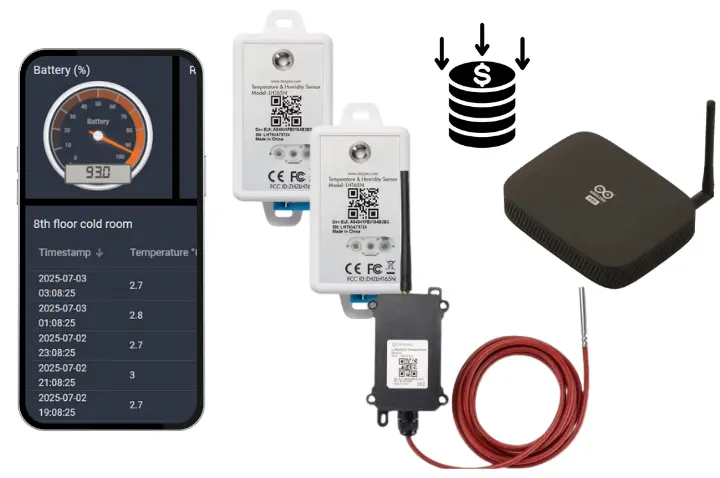

2. Food Grade Temperature Sensor & Cold Chain Temperature Sensor (Newly Launched)

Atomsenses newly launched Food Grade and Cold Chain Temperature Sensors are purpose-built to meet the demanding needs of temperature-sensitive industries from refrigerated storage to last-mile delivery.

Designed with precision and compliance in mind, these sensors help ensure food safety, regulatory adherence, and operational efficiency.

Real-World Deployment: Supporting Cold Chain Monitoring in Europe

Atomsenses newly launched Food Grade and Cold Chain Temperature Sensors are purpose-built to meet the demanding needs of temperature-sensitive industries from refrigerated storage to last-mile delivery.

Designed with precision and compliance in mind, these sensors help ensure food safety, regulatory adherence, and operational efficiency.

How It Works with IOTezy

Paired with the IOTezy cloud monitoring platform, users gain access to:

- Real-time temperature monitoring dashboards

- Historical temperature logs for audits

- Configurable alerts via SMS, email, or WhatsApp

- API integration with logistics and inventory systems

This integration empowers businesses to react quickly, reduce spoilage, and simplify compliance reporting.

Key Features

- Food-safe design with waterproof probe options

- LoRaWAN-based for wide-range, low-power operation

- Battery-powered or external power models available

- Temperature accuracy suitable for critical food & pharma monitoring

Ideal for:

- Cold chain logistics

- Refrigerated warehouses

- Restaurants, central kitchen

- Vaccine and pharmaceutical transport

Conclusion:

With strict temperature control becoming non-negotiable in food and medical supply chains, Atomsenses IAQ and temperature sensors, combined with IOTezy’s cloud platform they offer a scalable, compliant, and intelligent solution.