Cold Chain Monitoring

Ensure cold chain compliance with Real-Time IoT Monitoring

Challenges in Cold Chain

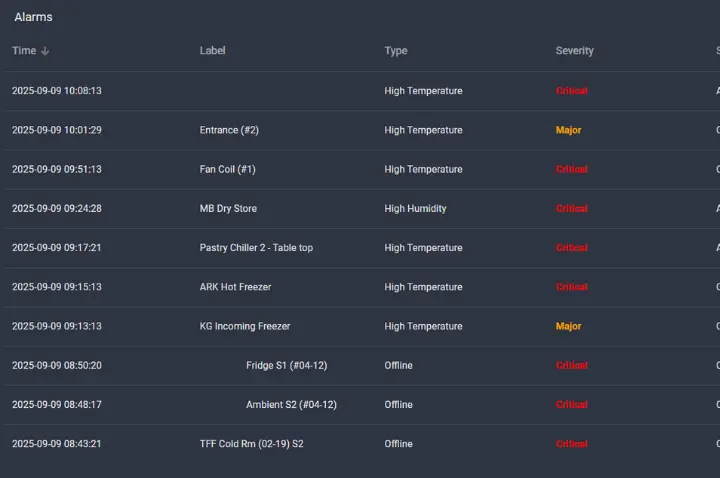

Maintaining strict temperature control across storage and transportation is critical but challenging. Many organizations still rely on manual logging and periodic checks, which are prone to errors, delayed responses, and incomplete records. These gaps increase the risk of product spoilage, compliance violations, and costly losses.

Equipment Failure Without Warning

Lack of Real Time Visibility and Intervention

Manual Temperature Logging Errors

High Rate of Product Spoilage

Strict Regulatory Compliance

Why It Matters

Protects Product Quality

Ensures temperature-sensitive goods stay within safe limits to maintain potency, freshness, and effectiveness.

Prevents Financial Losses

Reduces spoilage, waste, and costly recalls due to unnoticed temperature breaches or equipment failures.

Enables Regulatory Compliance

Helps meet industry standards like FDA, WHO, GDP, and HACCP with reliable data and audit-ready reports.

Supports Pro-Active Desicion Making

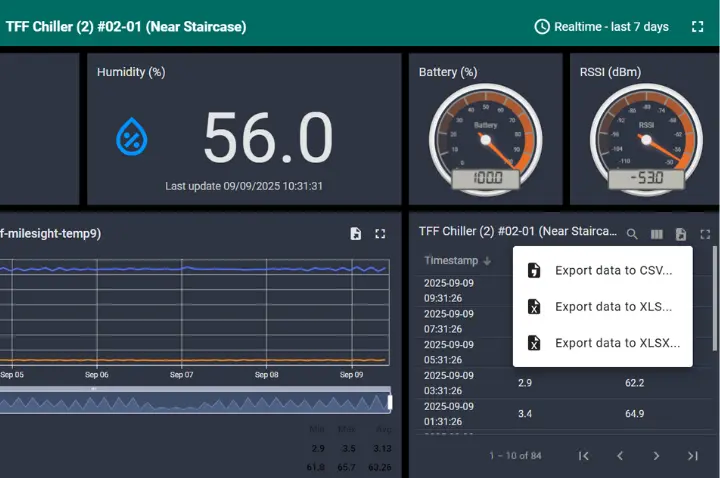

Enables quick response to anomalies and helps identify recurring issues through trend analysis.

Enhances Supply Chain Visibility

Provides real-time tracking and historical data across storage, transit, and delivery stages.

Improves Customer Trust

Demonstrates reliability and accountability, building confidence with clients and partners.

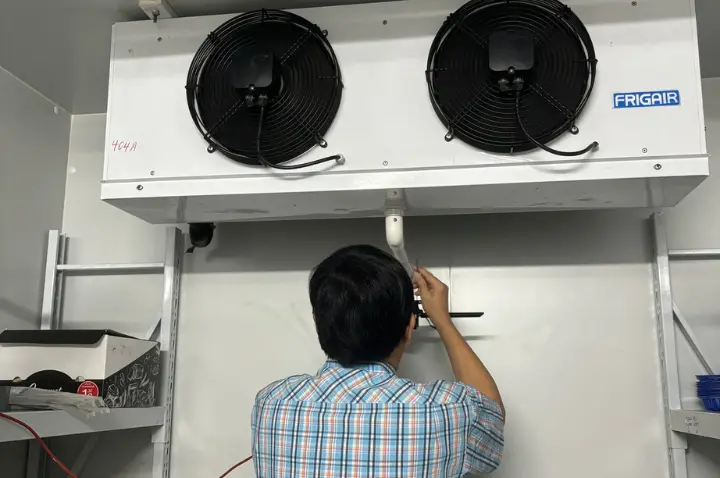

How Did We Solve It?

Solutions Used

Key Features

Ready to make work easy?

Get started with IOTezy, the tech behind workflow optimization.