Pharmaceutical Storage & Distribution

Ensure cold chain compliance with Real-Time IoT Monitoring

Challenges in Pharmaceutical Warehouse

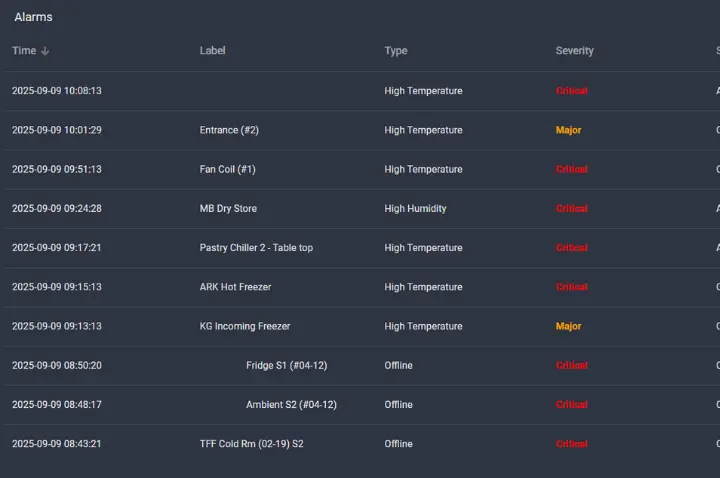

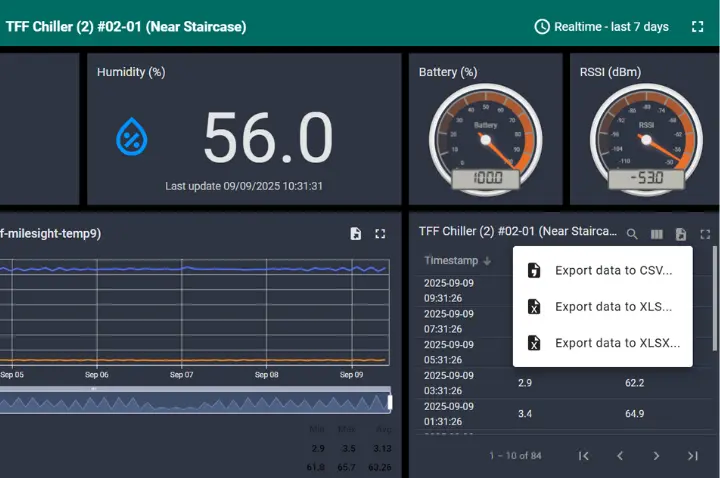

Pharmaceutical warehouses and distribution centers face strict requirements for temperature and humidity control to ensure drug safety and efficacy. Manual monitoring, lack of real-time visibility, and delayed response to equipment failures can lead to product spoilage, non-compliance, and costly losses.

Maintaining Temperature & Humidity Control

Risk of Product Spoilage Due to Equipment Failure

Manual Logging & Compliance Pressure

Lack of Real-Time Visibility

Supply Chain Disruptions

Why It Matters

Improves Traceability

Automatic data logging creates a verifiable trail of environmental conditions throughout storage and transit essential for quality assurance.

Protects Product Integrity

Many pharmaceutical products are temperature and humidity-sensitive, proper monitoring ensures they remain safe and effective for patients.

Reduces Financial Losses

Real-time alerts help prevent spoilage due to equipment failure, avoiding costly product write-offs and shipment rejections.

Enables Faster Response Times

Instant notifications let you act quickly when conditions go out of range, minimizing damage and disruption to the supply chain.

Enhances Supply Chain Visibility

Provides real-time tracking and historical data across storage, transit, and delivery stages.

Ensures Regulatory Compliance

Supports adherence to strict standards like GDP and GMP, reducing the risk of penalties or failed audits.

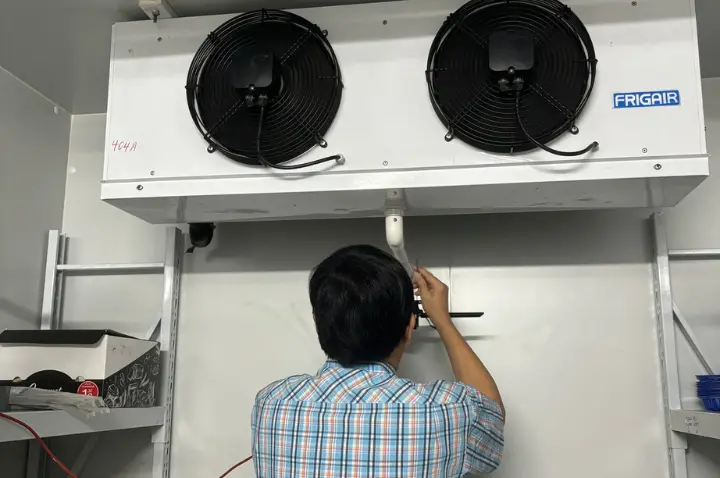

How Did We Solve It?

Solutions Used

Key Features

Ready to make work easy?

Get started with IOTezy, the tech behind workflow optimization.