IoT Monitoring vs Manual Checks: A Cost-Benefit Analysis

In today’s data-driven world, real-time IoT monitoring system is no longer a luxury it is a strategic advantage. But for many businesses, the question remains: Should we invest in IoT monitoring system, or stick with manual checks? This article breaks down the costs and benefits of both to help you make an informed decision. Read more on temperature monitoring system.

What is IoT Monitoring?

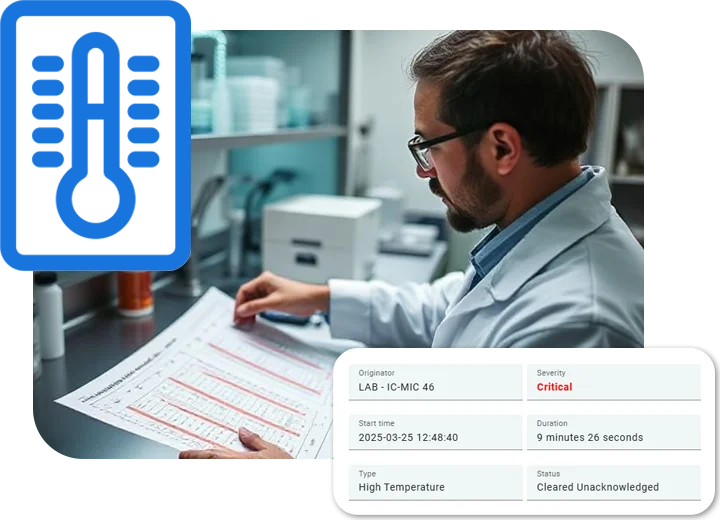

IoT (Internet of Things) monitoring refers to using internet-connected sensors to continuously track and report environmental or operational data such as temperature, humidity, motion, power usage, and more. These sensors often feed data to cloud dashboards, such as IOT-ezy plaform, receive alerts through Telegram, Email, Whatsapp and more.

What are Manual Checks?

Manual checks involve human workers regularly inspecting equipment, manually logging measurements (usually on paper or spreadsheets), and reporting anomalies or compliance data by hand.

Cost Benefit Comparison

| Factor | IoT Monitoring | Manual Checks |

|---|---|---|

| Initial Cost | High (hardware, installation, software) | Low (no tech required) |

| Ongoing Cost | Low (maintenance, cloud services) | High (labor-intensive, time-consuming) |

| Data Accuracy | High (automated, consistent) | Variable (subject to human error) |

| Frequency of Monitoring | Real-time (24/7) | Periodic (hourly, daily or weekly) |

| Scalability | Easy to scale by adding more sensors | Labor scales linearly with equipment/scope |

| Response Time | Instant alerts for anomalies | Delayed until next manual inspection |

| Compliance / Audit-Ready | Automatic logging, timestamps, historical data | Manual logs; harder to track and verify |

| ROI Over Time | High (especially in critical environments) | Low to moderate (labor-heavy and error-prone) |

| Human Labor Dependence | Minimal (after setup) | High (ongoing staffing required) |

Hidden Cost of Manual Checks

Manual monitoring may seem cheaper upfront, but can carry hidden costs:

- Human error: Misreadings, missed inspections

- Delayed response: Issues discovered too late (spoiled vaccines, food product not in right temperature resulting in food safety concerns)

- Labor costs: Overtime, night shifts, audits

- Compliance risk: Missing logs or incomplete data

- Limited scalability: Every added site means more staff needed

When IoT Makes Sense

In many warehouses or hospital settings, Wi-Fi coverage can be unreliable or restricted for security reasons. Traditional IoT devices that rely solely on Wi-Fi may lose connection, resulting in gaps in data logging. Now, modern IoT temperature monitoring solutions often use cellular connectivity, such as embedded SIM cards (like 1NCE SIMs), to securely and continuously send data to the cloud, regardless of Wi-Fi availability. This ensures uninterrupted monitoring and full visibility into your cold chain operations.

Conclusion: When Automation Pays Off

While manual checks have a lower barrier to entry, IoT temperature monitoring system delivers higher accuracy, speed, and cost-efficiency over time. For businesses aiming to grow, comply, or operate smarter, the shift to IoT is not just a tech upgrade it is a neccessity.

Start Monitoring with IOT-ezy

Explore our range of easy-to-install solutions today and start monitoring with confidence.