Real-life Monitoring Fails and What They Us About IoT

In the world of cold chain logistics, pharmaceuticals, and food safety, refrigeration monitoring is no longer a “nice-to-have” it is a necessity. And yet, time and time again, we see real-life examples of monitoring systems failing when they are needed most. These failures are not just expensive, they can jeopardize public safety, waste high-value inventory, and damage reputations.

So what goes wrong? And how can IoT-based refrigeration monitoring solve the problem? Learn more on refrigeration monitoring here.

Let’s dive into some real-world failures and the lessons they teach us.

Failure #1: Manual Logs Miss Critical Temperature Spikes

The Situation:

A pharmaceutical distributor was using manual temperature checks twice a day in their warehouse. Everything looked fine on paper, until a shipment arrived unusable due to prolonged exposure to heat.

What Went Wrong:

The cooling system failed for six hours overnight, long enough to damage the goods, but not long enough to be caught before the next manual check.

Lesson Learned:

Manual monitoring is not continuous. If you are not tracking in real time, you are missing gaps, and these gaps are where the losses happen.

How IoT Helps:

IoT refrigeration monitoring systems use real-time sensors that continuously track temperature and humidity. Alerts are triggered the moment values go out of range, even at 3 AM or outside working hours.

Failure #2: No In-Transit Monitoring for Cold Chain Shipment

The Situation:

A company shipped frozen food using standard reefer trucks. The onboard refrigeration system malfunctioned mid-journey, and the delivery team only realized when the cargo arrived partially thawed. The transport company had no visibility into what went wrong and could not prove when the failure occurred.

What Went Wrong:

There was no live in-transit monitoring or geolocation alerts.

Lesson Learned:

The cold chain does not stop at the warehouse. Without tracking during transit, you risk undetected spoilage and costly disputes.

How IoT Monitoring Helps:

With mobile-friendly IoT trackers, you can monitor temperature and location in real time, ensuring visibility from warehouse to final delivery.

Failure #3: Lack of Visibility in Multi-Temperature Facilities

The Situation:

A food storage facility had cold rooms with different temperature zones (frozen, chilled, ambient). Using a single sensor type and one monitoring system made it impossible to track all areas effectively. Some temperature-sensitive products were stored incorrectly, causing spoilage.

What Went Wrong:

Limited sensor diversity and lack of integrated monitoring created gaps.

Lesson Learned:

Cold chain monitoring must adapt to varied environments and product needs.

How IoT Monitoring Helps:

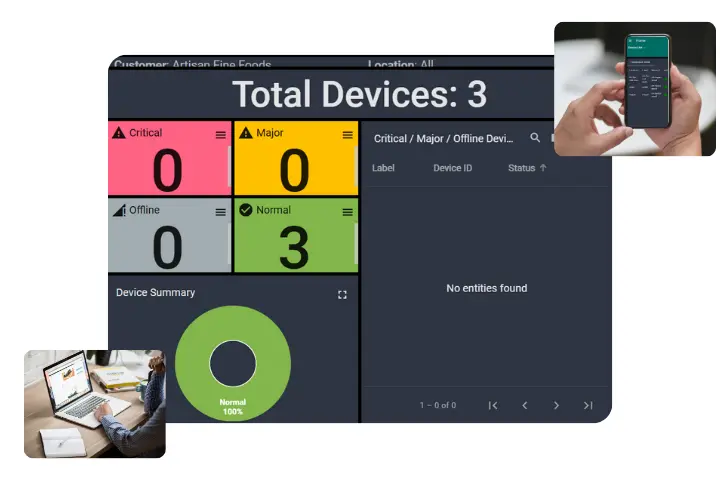

Flexible IoT platforms support multiple sensor types and zones, providing unified visibility across diverse temperature ranges.

From Failures to Smart Refrigeration Monitoring

These examples show that traditional methods, whether manual or outdated digital tools are no longer enough.

IoT-based refrigeration monitoring is not just about technology. It is about peace of mind, operational efficiency, and protecting high-value products in real time.

Key Features to Look for in a Modern Refrigeration Monitoring System:

- 24/7 tracking of temperature and humidity

- Instant alerts via multiple channels (Telegram, SMS, email)

- Data logging and compliance reporting

- Cloud access for remote monitoring

Shop Now at IOT-ezy

Protect Your Assets and Start Monitoring