Why an IoT Temperature Monitoring System is Essential For Modern Businesses

Maintaining the right temperature is critical for any business handling food, pharmaceuticals, or sensitive equipment. As operations grow more complex and compliance standards get stricter, manual temperature checks are no longer enough. That’s where IoT-driven automation comes in.

At IOT-ezy, our temperature monitoring system helps businesses track conditions in real time, prevent losses, and stay fully compliant all through smart, connected technology.

What is an IoT Temperature Monitoring System?

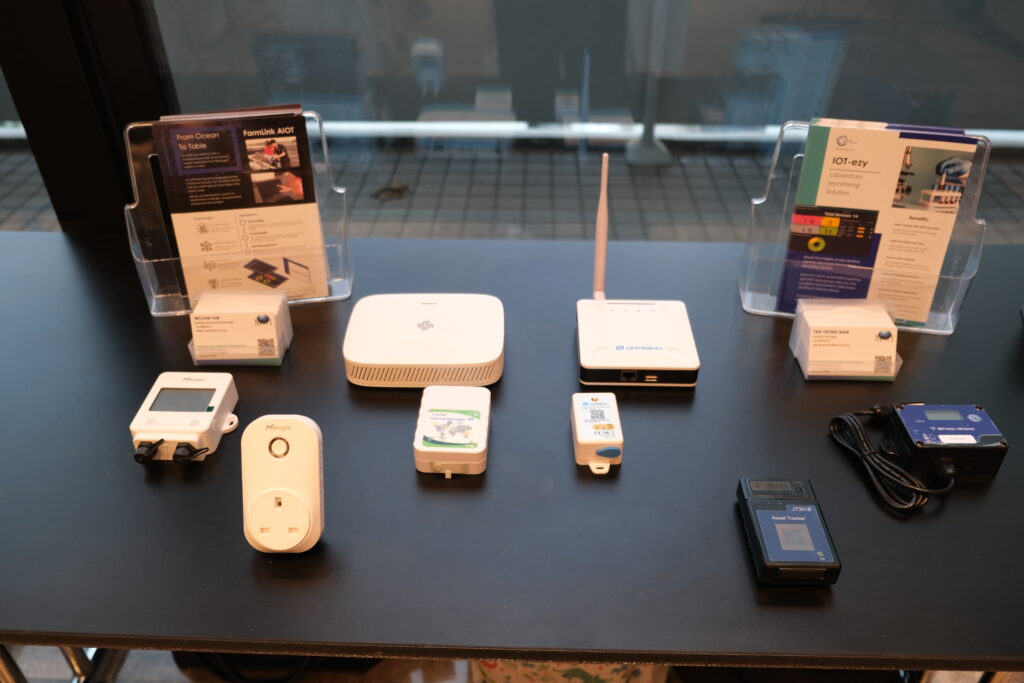

A temperature monitoring system is a solution made up of sensors, communication modules, and software that continuously tracks temperature conditions in real time. IoT (Internet of Things) elevates this concept by enabling:

- Wireless sensors that monitor temperature conditions 24/7

- Instant alerts when temperatures go out of range

- Cloud dashboards to view data anytime, anywhere

- Automated reporting that reduces manual workload

- Predictive analytics to prevent equipment failures

IOT-ezy combines these technologies into an easy-to-deploy, secure, and cost-effective platform.ns that offer smarter, faster, and more reliable control.

Why Temperature Monitoring Matters?

Temperature-sensitive environments require precise monitoring to avoid spoilage, contamination, equipment breakdown, or regulatory non-compliance. Industries such as:

- Cold storage & refrigeration

- Restaurants & food chains

- Pharmacies & vaccine storage

- Logistics & cold-chain transport

- Manufacturing & industrial facilities

A single temperature deviation can lead to product loss, costly recalls, or safety violations. That’s why having an IoT-based automated system is no longer optional — it’s essential.

Key Features of IOT-ezy Temperature Monitoring System

1. Real-Time Temperature Tracking

Our sensors continuously capture temperature data and push it to the cloud dashboard so you always know what’s happening.

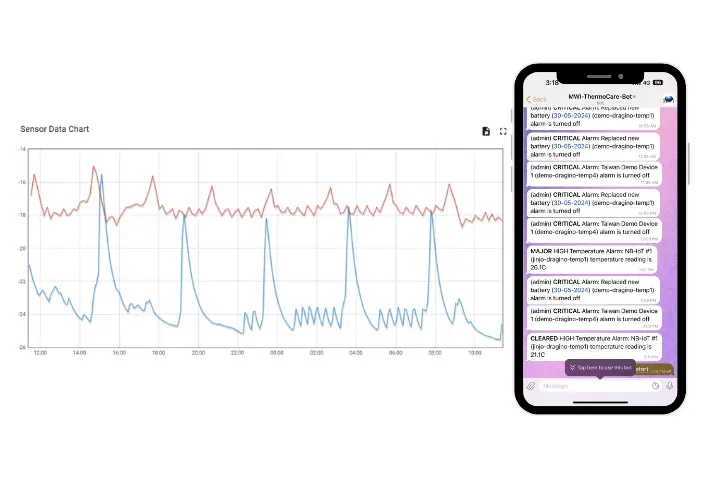

2. Instant Alerts & Notifications

Receive SMS, WhatsApp, email, or push notifications the moment temperatures move out of range, enabling rapid action.

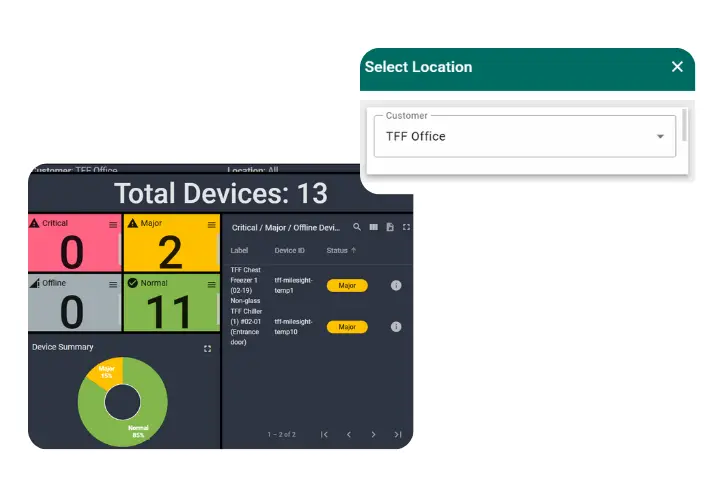

3. Cloud-Based Dashboard

IOT-ezy provides a user-friendly dashboard where you can view trends, check sensor status, and download historical logs.

4. Automated Compliance Reports

Perfect for industries needing detailed temperature logs for audits, HACCP, FDA, GMP, or MOH requirements.

5. Easy Installation & Scalability

Our wireless sensors require minimal setup and can scale across multiple locations, whether you manage one site or hundreds.

6. Long Battery Life & Low Maintenance

Sensors are optimized for low power consumption with extended battery life, reducing the need for frequent replacements.

Benefits of IoT Temperature Monitoring for Your Business

✔ Prevent Product Loss

Automated alerts help you take immediate action before spoilage occurs.

✔ Improve Operational Efficiency

No more manual temperature checks — staff can focus on core tasks.

✔ Reduce Equipment Downtime

Predictive analytics help you identify potential equipment issues early.

✔ Ensure Regulatory Compliance

Maintain detailed, timestamped temperature records for inspections and audits.

✔ Lower Operational Costs

Reduce waste, prevent asset damage, and optimize energy consumption. everything from scratch, businesses can leverage expertise, save time, and focus on their core operations.rity.

Use Cases of IOT-ezy’s Temperature Monitoring System

Food & Beverage

Monitor chillers, freezers, and cold rooms to ensure food safety.

Healthcare & Pharmaceuticals

Track temperature-sensitive medicines, vaccines, and laboratory samples.

Cold Chain Logistics

Monitor shipments throughout transportation for end-to-end visibility.

Industrial Manufacturing

Ensure stable environmental conditions for production efficiency.