AI + IoT: The Future of Predictive Monitoring Is Already Here

In today’s global supply chain, maintaining product quality from source to destination is critical, especially in temperature-sensitive industries like pharmaceuticals, food & beverage, and biotechnology. Cold chain monitoring plays a central role in ensuring that products stay within safe temperature ranges throughout transport and storage. But what if you could predict problems before they happen?

Enter AI + IoT-powered predictive monitoring a game-changing approach that’s redefining cold chain logistics.

What is Predictive Monitoring in Cold Chain?

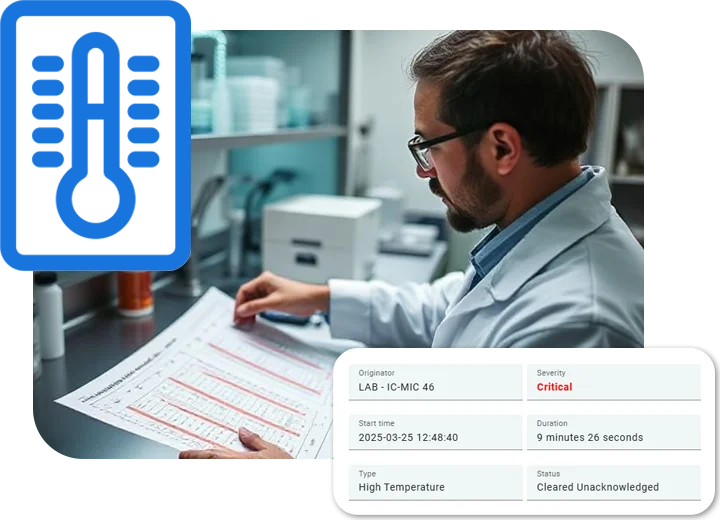

Predictive monitoring uses artificial intelligence (AI) and Internet of Things (IoT) to analyze real-time and historical data from cold chain assets such as refrigerated trucks, storage units, or cold rooms). Unlike traditional monitoring systems that simply alert you after a failure occurs, predictive monitoring identifies potential risks in advance, helping businesses to act before incidents happen.

How AI + IoT Work Together for Cold Chain Monitoring

IoT sensors are placed in cold chain environments to continuously track conditions like:

- Temperature

- Humidity

- Location

- Door open/close status

This real-time data is transmitted to cloud platforms where AI algorithms analyze patterns and detect anomalies. For example, if a refrigerated container starts showing a pattern of fluctuating temperatures before compressor failure, AI can flag this early, preventing potential spoilage and save costs or compliance breaches.

Key Benefits of AI-Driven Predictive Monitoring in Cold Chain

1. Prevent Product Loss

AI helps identify trends that point to future equipment failure, temperature deviations, or human error, reducing spoilage and saving money.

2. Ensure Compliance and Safety

Pharmaceuticals and vaccines must adhere to strict regulations (like HSA, ISO, or GDP). Predictive monitoring ensures that cold chain conditions are maintained consistently, with digital records available for audits.

3. Improve Operational Efficiency

By automating alerts and reducing manual checks, businesses can reallocate labor and reduce inefficiencies.

4. Optimize Maintenance

Predictive maintenance, powered by AI means equipment is serviced when it needs it, not just on a calendar schedule, reducing downtime and extending asset life.

Use Cases of Predictive Monitoring in Cold Chain

Pharmaceutical Distribution: Prevent vaccine or drug spoilage due to minor fluctuations in temperature by predicting equipment failure.

Food Logistics: Avoid contamination or waste in perishable goods by identifying refrigeration issues before transport begins.

Retail & Grocery Chains: Maintain product quality from warehouse to shelf with full visibility across refrigerated supply chains.

Why Predictive Monitoring is the Future of Cold Chain

As global supply chains become more complex and regulations tighter, reactive cold chain monitoring is no longer enough. Predictive monitoring, powered by AI and IoT, offers real-time intelligence that reduces risk, boosts efficiency, and ensures compliance, making it an essential investment for future-proofing your operations.

Shop for Sensors Here

Explore our range of easy-to-install solutions today and start monitoring with confidence.