The Future of Cold Chain Monitoring: AI, IoT, and Predictive Alerts

Keeping temperature-sensitive goods safe isn’t just about checking thermometers anymore. Today’s supply chains need smarter, faster, and more connected solutions. That’s where the new era of cold chain monitoring comes in – driven by AI, IoT, and predictive alert systems that think ahead instead of reacting too late.

From real-time data to automated insights, these technologies are giving businesses unprecedented control and visibility over their cold chain – ensuring that quality and safety are never compromised.

The Limitations of Traditional Cold Chain Systems

Conventional temperature monitoring often depends on manual checks or simple data loggers that record temperature history without real-time insight. By the time deviations are detected, it’s usually too late – the product has already been compromised.

These legacy systems lack:

- Real-time visibility into temperature fluctuations

- Automated alerts for quick response

- Data intelligence to predict risks or equipment failures

That’s why businesses are increasingly turning to IoT-based cold chain monitoring solutions that offer smarter, faster, and more reliable control.

IoT: The Foundation of Modern Cold Chain Monitoring

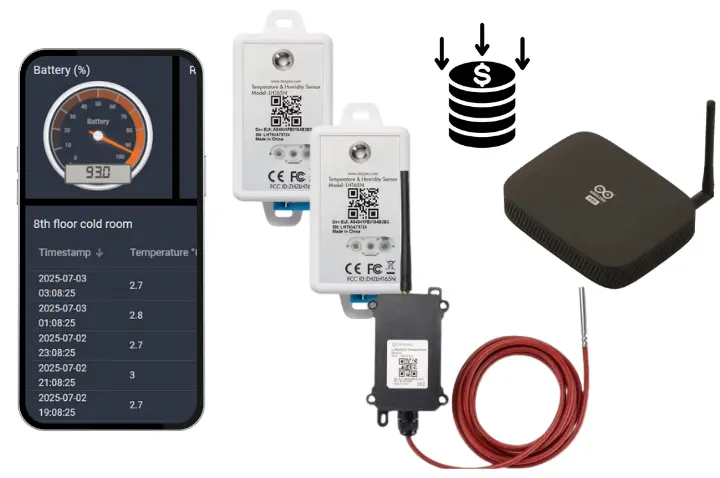

IoT technology forms the backbone of modern cold chain monitoring systems. With wireless sensors placed in storage units, trucks, and warehouses, temperature and humidity data can be tracked continuously in real time.

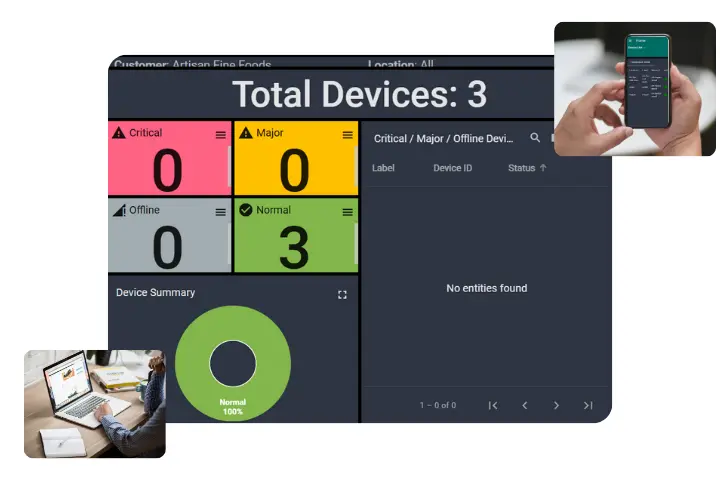

IOT-ezy’s IoT sensors automatically send data to a secure cloud platform, giving businesses instant access to:

- Live temperature dashboards

- Location-based asset tracking

- Automated alerts for threshold breaches

- Centralized reports for compliance and audits

This automation not only eliminates manual logging but also ensures data accuracy – a crucial factor for sectors that depend on regulatory compliance like F&B and pharmaceuticals.

AI and Predictive Analytics: From Reactive to Proactive

The next evolution in cold chain monitoring is intelligence – systems that can predict potential issues before they happen.

By applying AI and predictive analytics, IoTezy enables businesses to:

- Identify unusual temperature patterns or sensor behavior

- Forecast equipment failures or power fluctuations

- Automatically trigger maintenance or backup systems

- Optimize energy use for efficiency and sustainability

For example, if a cold room’s compressor begins to fail, AI algorithms can detect early warning signs – such as slow recovery times or irregular temperature cycles – and alert staff before a breakdown occurs.

This proactive approach turns cold chain monitoring from a reactive safety measure into a strategic advantage.

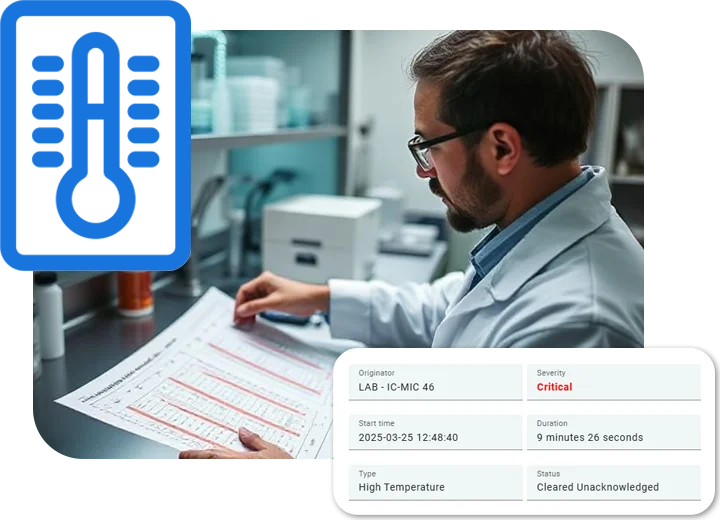

Predictive Alerts: Real-Time Protection, 24/7

Predictive alerts are at the heart of IoTezy’s innovation. Unlike basic alarm systems that notify you after a problem occurs, predictive alerts use AI models to assess data trends and identify risks early.

Businesses can receive notifications via SMS, WhatsApp, or email – giving teams the chance to respond immediately and prevent losses. This capability is especially valuable for 24/7 operations such as:

- Food distribution and storage

- Vaccine logistics

- Hospitality and catering services

The result? Fewer temperature excursions, less spoilage, and greater confidence in your cold chain integrity.

Sustainability Through Smart Cold Chain Monitoring

Sustainability is another key driver for innovation in this space. Smarter cold chain monitoring reduces food waste, optimizes energy consumption, and lowers carbon emissions.

By enabling precision control and predictive maintenance, IoTezy helps businesses run more efficiently – achieving their environmental goals while saving costs in the long term.

Stay Ahead with IOT-ezy

At IOT-ezy, we believe technology should empower, not complicate. Our intelligent cold chain monitoring solutions make it easy for companies of all sizes to protect products, reduce waste, and operate sustainably.